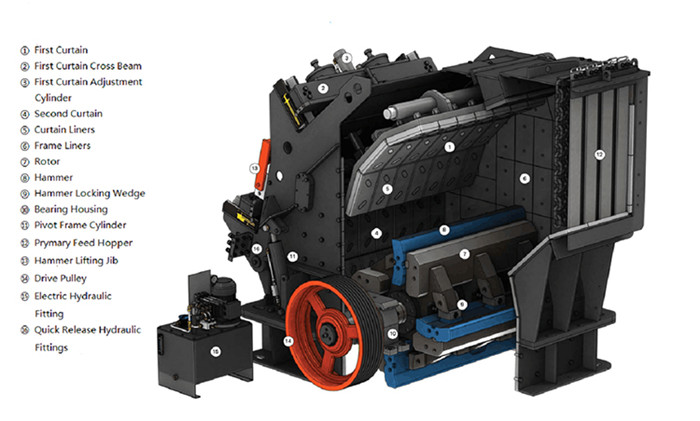

Impact crusher has the advantages of large crushing ratio and good material particles. Its crushing principle is to use its fast rotating blow bars to impact the material, so that the material will eventually become the required size particles after repeated impact.

When the material enters the crushing cavity from the feeding port, the material will get a higher speed due to the high-speed impact of the high chrome alloy blow bars, and the material will be crushed for the first time; When the material rebounds back from the primary liner, it collides with the blow bars again, and the material is impacted on the secondary liner plate again by the plate blow bars.

At this time, the second crushing occurs; In the crushing chamber of the crusher, when the materials are impacted by the blow bars, the materials also collide with each other, and there is also crushing effect between the materials, blow bars and lining plate, so that the materials can be broken in the free state in the crushing chamber of the crusher.

The material enters the crushing chamber, and after repeated impact crushing by blow bars and liner plate, it enters the lower box. At this time, the material grinds with the sieve plate, causing the material to be broken again; The above process is repeated until the particle size of the crushed material is less than the gap between the blow bars and the liner plate, and then the material is discharged from the sieve plate of the impact crusher, which is the particle size required after crushing.