Applicable Materials:

Chemical Component

River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Working condition:

sand-gravel yard, mine mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

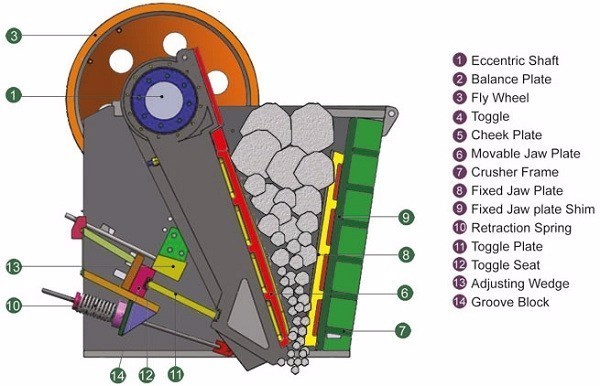

Application Machine: All kinds of jaw crusher.

Material

Chemical Composition(%)

Mechanical Property

C

Si

Mn

Cr

Ak/cm

HB

Mn13Cr2

1.1~1.4

1.7~2.2

12~15

1.7~2.2

>140

≤220

Mn18Cr2

1.1~1.4

1.7~2.2

17~19

1.8~2.2

>140

≤230

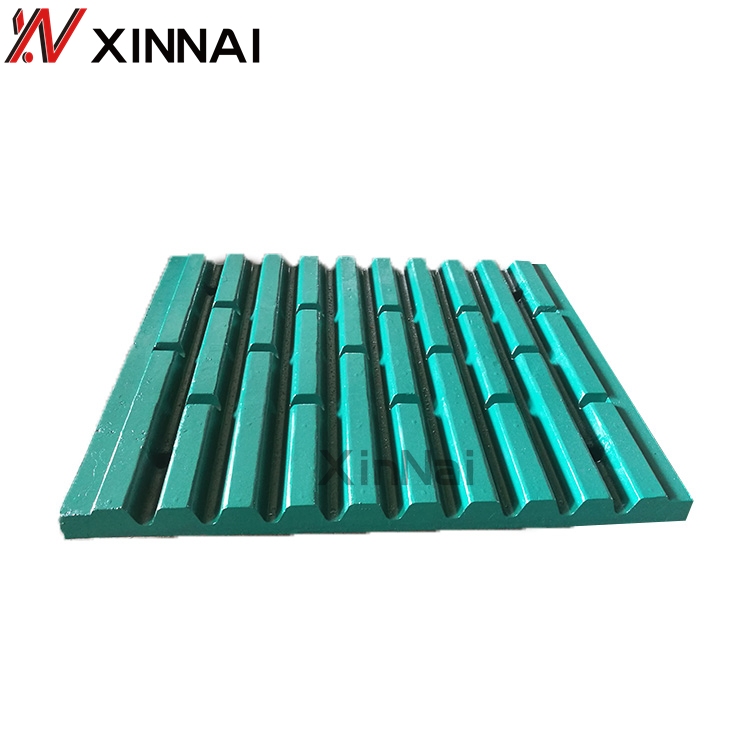

The main characteristics of jaw plate are good toughness and good resistance to deformation and hardening.

The jaw plate is made of ZGMn13Cr2 pouring material. We add a certain amount of chromium material in the high manganese steel, improving the hardness, in the meantime, doing water toughening treatment also improve its tensile strength, toughness, plasticity and non-magnetic, so that the jaw plate is more durable.