Applicable Materials:

River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Working Condition:

sand-gravel yard, mine mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Application Machine: all kinds of crusher

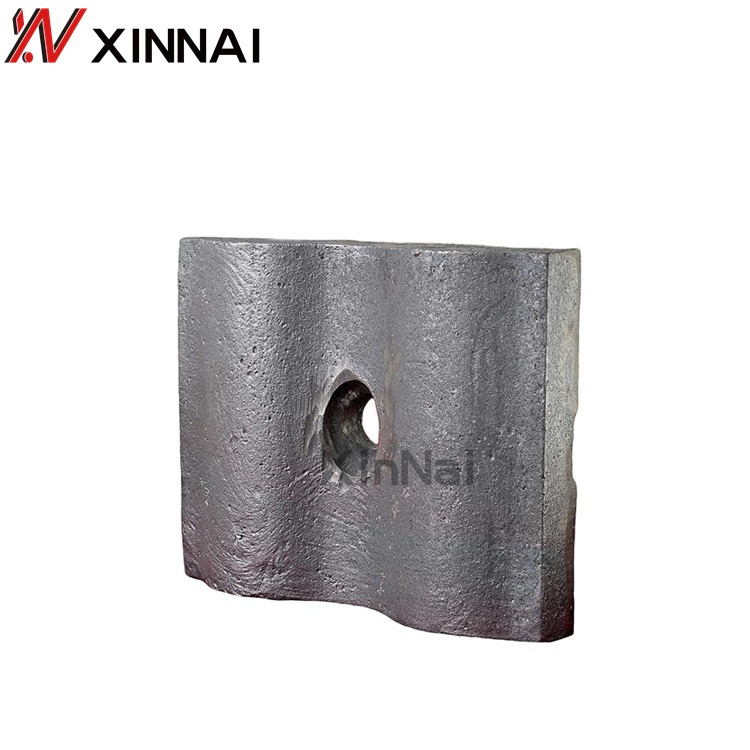

Ball mill liner plate can protect the inner wall of the ball mill, so that the ball mill can avoid the direct impact and friction from the grinding media, at the same time, different forms of ball mill liner plate can adjust the motion state of the grinding media, enhance the grinding effect of the grinding media on the material, help to improve the grinding efficiency of the ball mill, increase the output, reduce the consumption of the grinding media.

In order to adapt to different working condition (grinding and fine grinding), the shape and material of ball mill liner are different also, when it is mainly grinding, it is required the ball mill liner plate has relatively strong lifting ability to the grinding media, and also needs the liner plate have good impact resistance, also requires a lining board needs to have good shock resistance, when is given priority to fine grinding, the bump of the liner plate is smaller, weak lifting ability on grinding meida and the impacting is weak, but the grinding effect is stronger, requiring the liner plate have good wear resistance.

Package:

Features:

Low-weight, high-strength designs create less stress on mill bearings and reduced torque requirements

Excellent sealing properties eliminate mineral lock-up, improving the recovery of valuable products

Blinding of grate plates is virtually eliminated, increasing throughput

Low liner weight enables safe installation by hand. No mill liner handler required!

Low noise levels enhance working conditions