Applicable Materials:

granite, basalt, limestone, river pebbles, cement clinker, quartz stone, iron ore, bauxite, salt, brick, coal, etc.

Working condition:

Gravel yard, concrete sand, dry mortar, machined sand, power plant desulfurization, quartz sand, etc.

Chemical Component Ratio(%)

Hammer head<working part> 59-61HRC

Hammer shaft<hammer head> 35HRC

C

Mn

Cr

Mo

Ni

Cu

Si

C

Mn

Si

2.0~3.3

0.8~1.2

18~22

≥0.8

0.4~0.6

0.8~1.2

≤0.8

0.33~0.36

0.60~0.80

0.4~0.5

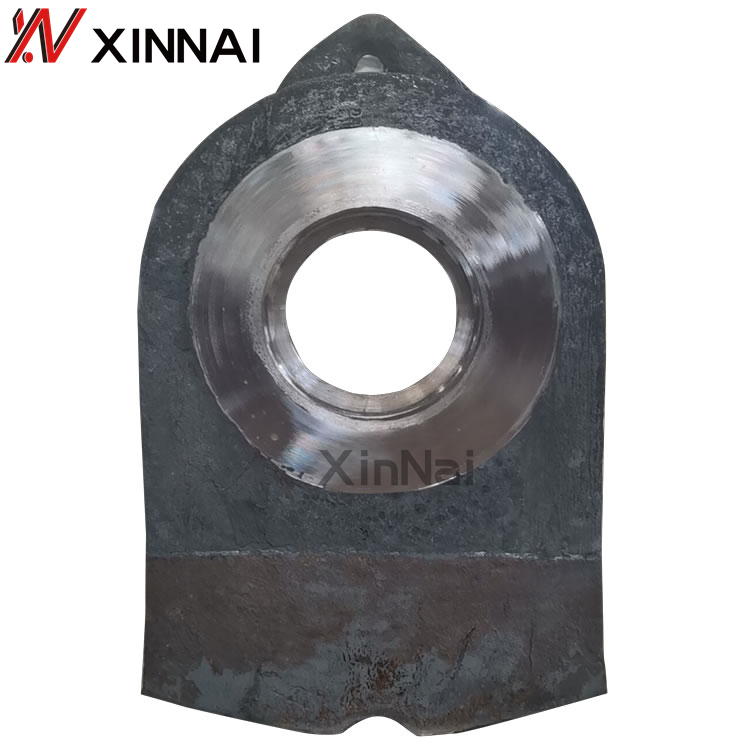

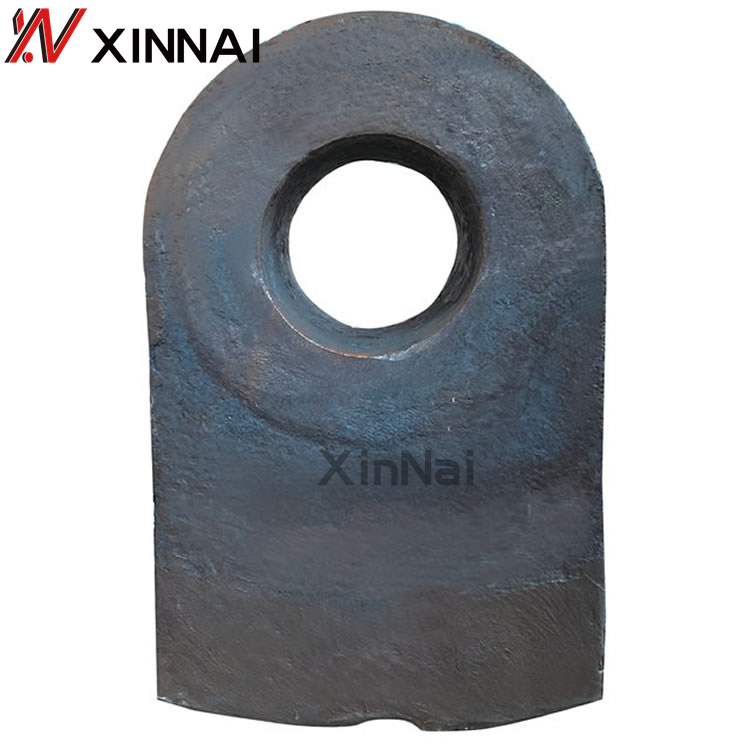

Crusher Bimetal hammer’s shaft part is made of low alloy steel, which has good toughness and is not easy to break. The hammer's head part is made of high chromium alloy, which has better wear resistance. The two parts are organically combined with special production technology to meet the requirements of toughness and wear resistance at the same time. After the water toughening treatment and low temperature tempering, the composite microstructure is martensite and eutectic carbide.

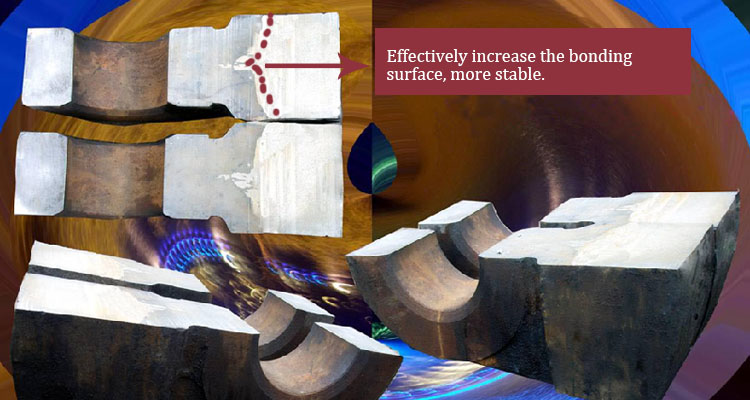

1. Two-liquid fusion of the casting completely combined together, there is no cold separation, cracks,inclusions and other defects, the structure is compact.

2. The running time is 27-35h, under the same working conditions, the life time is more than 3 times than the hammer with high manganese steel.

Bimetal hammer is the main wear parts for hammermill crusher. The other main wear parts are liner, grid plate and etc.

Various brands of hammer crusher spare parts can be made by us, also can customized according to the client’s working condition.

Hammer crusher is suitable for the crushing of various materials in cement, mining, power, metallurgy, chemical and other fields.