Applicable Materials:

River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Working condition:

sand-gravel yard, mine mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Application Machine: All kinds of crusher.

Chemical Component :

Material

Chemical Composition(%)

Mechanical Property

C

Si

Mn

Cr

Ak/cm

HB

Mn13Cr2

1.1~1.4

1.7~2.2

12~15

1.7~2.2

>140

≤220

Mn18Cr2

1.1~1.4

1.7~2.2

17~19

1.8~2.2

>140

≤230

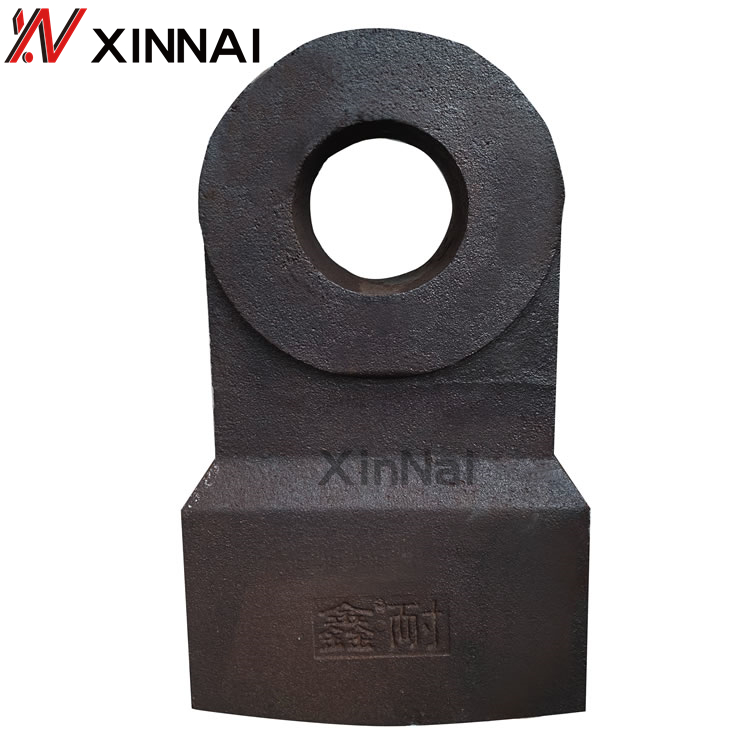

General Description

1) . Material: 13%Mn2%Cr,18%Mn2%Cr,21%Mn2%Cr

High manganese steel has good plasticity and impact toughness. Under the impact of external force, the hardened surface layer is produced. After the hardened surface layer is worn, a new surface layer appears, and then continues to be machined and hardened.Therefore, the high manganese steel castings have high surface wear resistance, and the inner part still retains the original mechanical properties. At present, there is no wear-resisting material in the world that can completely replace the high manganese steel.

2). Technological process:

Every model is tested for shock, stress, strain, thermal loading, deformation, vibration and noise under a wide range of load conditions.

The special processing techniques ensure our products has leading performance.

3). Product quality testing:

High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment.

4) . Performance:

High manganese steel material make the hammer with longer wear life and excellent performance, save the time of replacement and get the maximum potential out of the hammermill crusher

For the hammermill crusher, the main working part of the hammer crusher is the rotor with hammer head. The rotor is composed of main shaft, disc, pin shaft and hammer head.The material is fed into the machine from the upper feed port and crushed by the impact, impact, shearing and grinding of the high-speed hammer.

1. Withstand high impacts, the shank must have high strength and toughness combined with comprehensive mechanical properties. The hammer head should have high hardness and high wear resistance-composite hammer head is the best choice.

2. Hammer head, sieve plate, various lining plates of hammer crusher.

3. Suitable Material:High chrome,bimetal composite,high manganese steel,high manganese insert alloy bar,high manganese welding,medium alloy ,ceramic composite.