Applicable Materials:

River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Working condition:

sand-gravel yard, mine mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Application Machine: all kinds of crusher

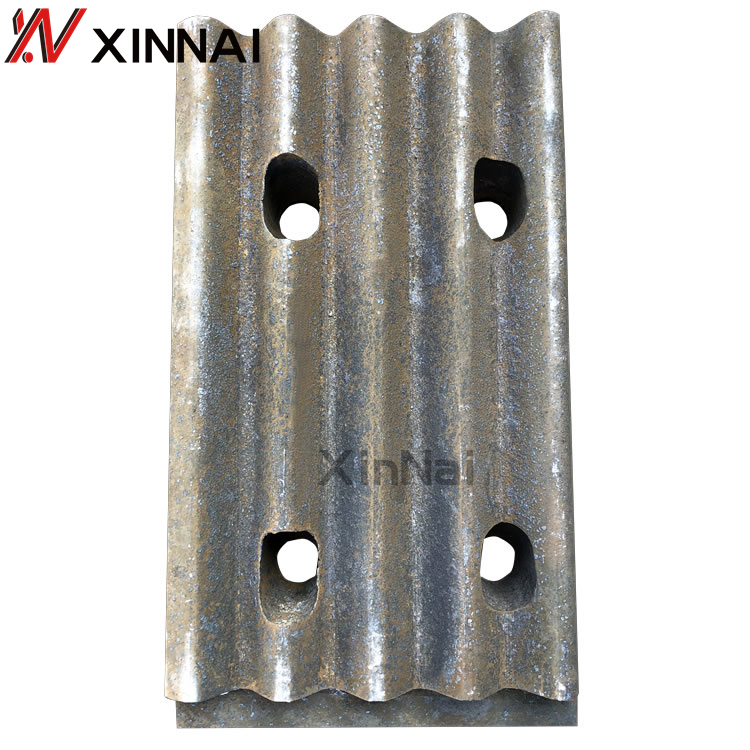

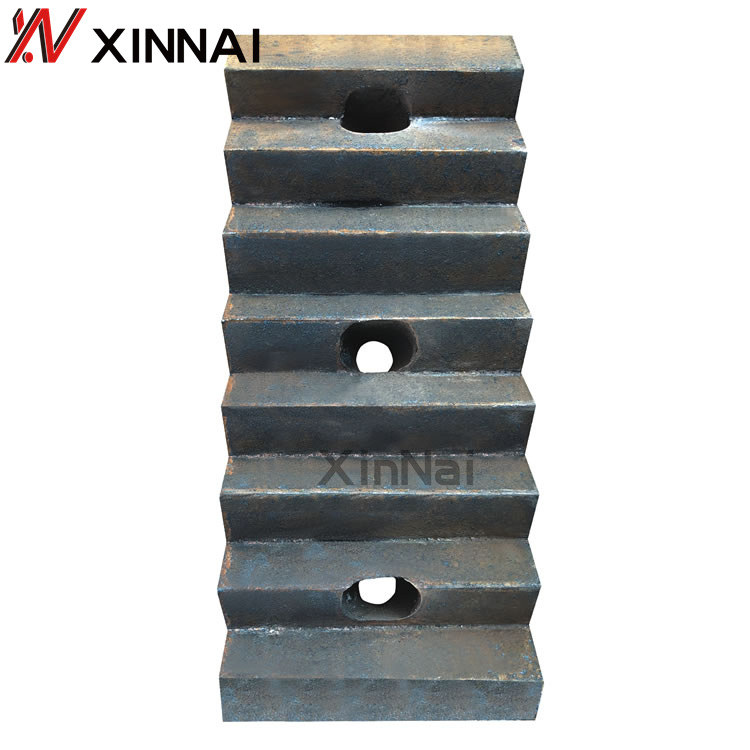

High manganese steel alloy liner plate can protect the inner wall of crusher equipment, so that it is free from the direct impact and friction of materials or other material blocks entering the inner cavity. Different types of high manganese steel alloy liner plate can adjust the movement state of materials, strengthen the crushing effect of crusher equipment on materials, improve work efficiency and increase output. In the process of crusher operation, the liner will undergo the impact and friction of large materials, and wear quickly, so it is required that the liner has strong wear resistance and impact resistance. High manganese steel material is easy to produce work hardening under high impact force, especially in the impact of the working condition, its surface hardening thickness can reach 10-20mm, high hardness hardening layer can resist impact abrasive wear, under strong impact conditions, wear resistance performance is outstanding.

High manganese steel alloy liner plate produced by Xinnai is with water toughness treatment, that make it have better wear resistance and impact resistance.

Feature:

1. Main material: Mn13, Mn13Cr2, Mn18Cr2Mo, and also adding appropriate amount of Mo, Ni, Ti and other multi-alloy in the basis of Mn13Cr2.

2. Toughness and wear resistance, long service life, reduce the number of replacement, improve the working efficiency of the crusher.

3. With cold work hardening technology, high hardness.

4. Water toughness treatment, to avoid the natural phase during using process.