Applicable Materials: River pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc

Working condition: sand-gravel yard, mine mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

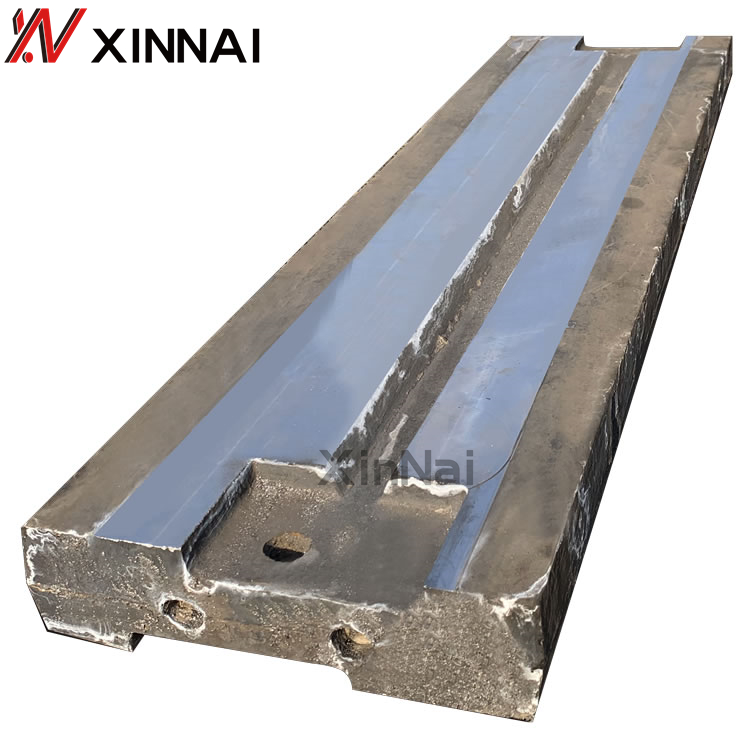

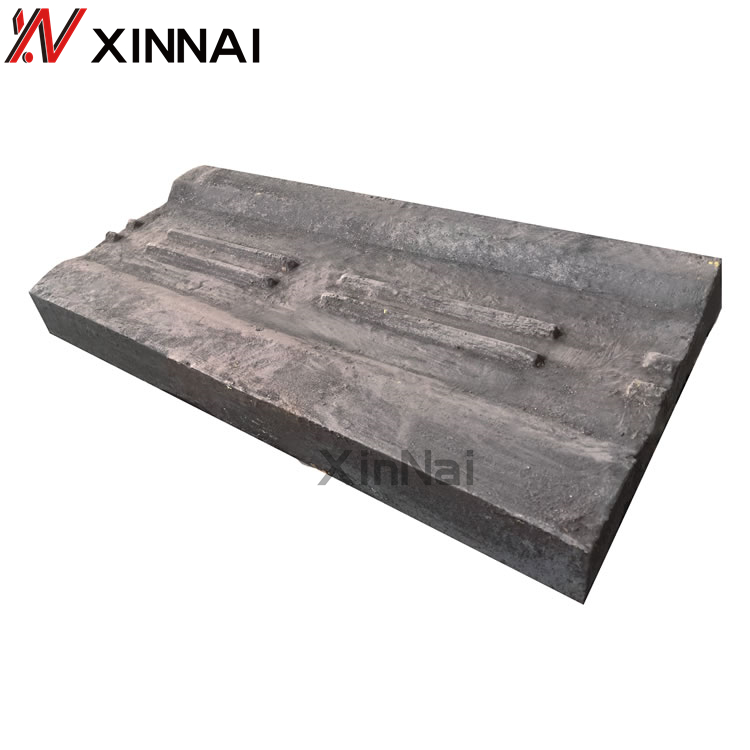

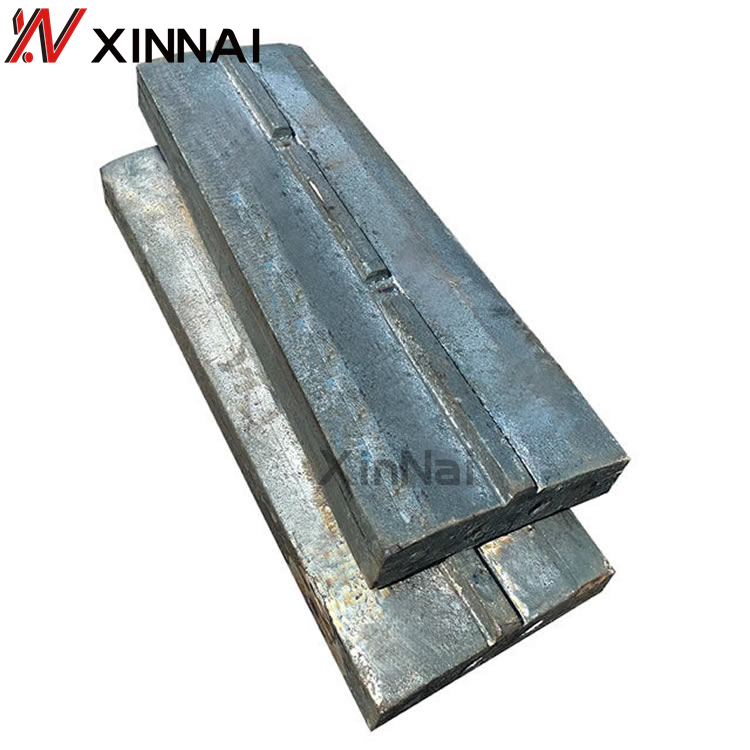

High chromium plate hammer(blow bar) is widely used for impact crusher, it is made by high chromium alloy (Cr26) , the HRC of high chromium alloy can reach 65, comparing with similar products, it has better hardness, wear resistance and other comprehensive performance, high reliability, high resistance to wear, high cost performance, especially suitable for the corrosive limestone that with high silicon content and not easy to be broken, its excellent performance has been successfully recognized and adopted by many large crushing production lines.

In the process of plate hammer(blow bar) casting, Xinai Casting has added a variety of rare metal material such as tungsten, titanium, chromium and nickel, and treated with alloy modifier to strengthen the substrate. Adopt advanced technology such as refining outside furnace, vacuum casting and directional solidification to further increase grain refinement and achieve better performance.

Specification:

Product Name

Blow Bar (hammer plate)

Machine Type

Impact Crusher

Material

manganese steel, chrome steel, ceramic insert and customised material

Production Test

Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment.

Life Time

100% match original OEM quality

Production Type

Casting

Surface Treatment

Polishing

Package: