Jaw crusher is widely used in coarse crushing and medium crushing in mining, metallurgy, construction and other industries. The jaw crusher features large crushing ratio, high output, simple structure, uniform crushing granularity and simple maintenance. The crusher mainly crush large particle materials by external power small particle size material. The working principle and mode of jaw crusher belong to the typical splitting and crushing.

In the process of relative operation of two parts with wave working surface, the material is broken into small particles and the crushing process is completed. The crushing of many nonferrous mines is the first step in smelting process. The particle size of materials after the crushing process, namely the crushing capacity, is an important index to measure the crushing process.

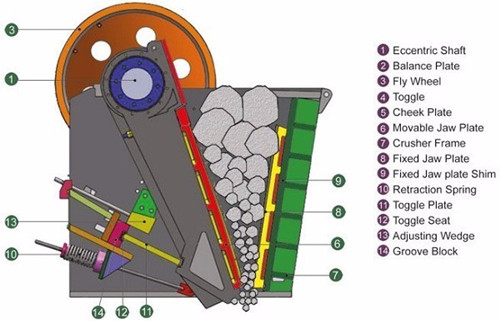

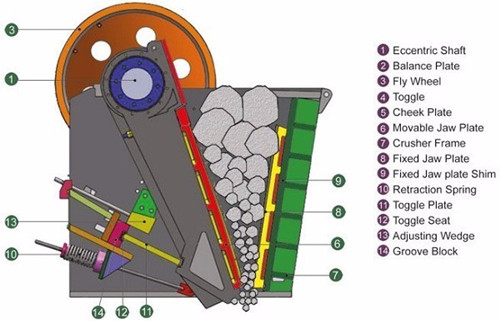

The upper part of the crusher's movable jaw plate is directly set on the eccentric shaft, and the lower part is connected with the thrust rod. The thrust rod adjusts the installation position of the lower part of the movable jaw through the bolt top bar to realize the change of the distance between the movable jaw plate and the fixed jaw plate, so as to ensure that the blanking port meets the requirements of the process production. Flywheel is installed at both ends of eccentric shaft, and flywheel on one side is pulley to transmit power. When the motor drives the pulley and drives the eccentric shaft to rotate anticlockwise, the movable jaw plate oscillates in complex reciprocating manner. The upper part of the movable jaw plate is approximately circular motion, and the lower part is divided into elliptical motion. This composite motion not only provides crushing force, but also produces grinding force. When the material is fed, the top of the jaw plate enters the crushing chamber, and the space between the dynamic and static jaw plates is the crushing chamber. The motor drives the belt, drives the pulley, and the pulley transmits the torque to the movable jaw plate through the eccentric shaft, which causes the movable jaw plate to move up and down, and up and down When the moving jaw plate is raised, it gets close to the fixed jaw plate, and the material is pressed, rubbed and crushed into small particles; When falling, the movable jaw plate leaves fixed jaw plate under the external force, and the distance between the two is expanded. The materials just broken can be discharged from the feeding port. The motor works continuously, and the crusher breaks and eliminates periodically, and realizes mass production.